Jyk87d8fj↑↑↑Black Hat SEO backlinks, focusing on Black Hat SEO, Google Raking

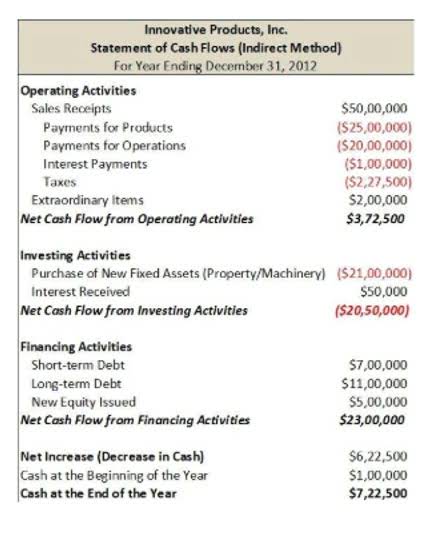

We focus on financial statement reporting and do not discuss how that differs from income tax reporting. Therefore, you should always consult with accounting and tax professionals for assistance with your specific circumstances. Some valuable items that cannot be measured and expressed in dollars include the company’s outstanding reputation, its customer base, the value of successful consumer brands, and its management team. As a result these items are not cash flow reported among the assets appearing on the balance sheet. The income statement, statement of cash flows, statement of comprehensive income, and the statement of stockholders’ equity report information for a period of time (or time interval) such as a year, quarter, or month. Usually financial statements refer to the balance sheet, income statement, statement of comprehensive income, statement of cash flows, and statement of stockholders’ equity.

- For example, sales commissions and shipping costs for a specific product could be assigned to the product.

- The income statement is also referred to as the profit and loss statement, P&L, statement of income, and the statement of operations.

- A word used by accountants to communicate that an expense has occurred and needs to be recognized on the income statement even though no payment was made.

- Consider a Canadian automotive parts manufacturer that implemented a cost management strategy focusing on reducing manufacturing overhead.

- Indirect labor (part of manufacturing overhead) includes the production supervisors who oversee production for several different boats and product lines.

- They are matched with the revenues of a specific time period rather than included in the cost of the goods sold.

Nonmanufacturing Costs

Next, you will need to https://www.bookstime.com/ allocate the cost of the activities to the individual products. Estimates and allocations based on logical assumptions are better than precise amounts based on faulty assumptions. From the table you can see that direct materials are the integral part and a significant portion of finished goods. A manufacturing entity incurs a plethora of costs while running its business. While manufacturing or production costs are the core costs for a manufacturing entity, the other costs are also just as important as they too affect overall profitability. Thus, management attention must be focused on both the core and the ancillary costs to control and manage them with a view to maximize profitability on long term basis.

Presentation of Nonmanufacturing Overhead Costs

Non-manufacturing nonmanufacturing costs costs are called period costs and are expensed in the period incurred. In summary, non-manufacturing costing is a vital aspect of measuring the total cost of providing services or performing functions. All manufacturing costs that are easily traceable to a product are classified as either direct materials or direct labor. All nonmanufacturing costs are not related to production and are classified as either selling costs or general and administrative costs.

- Distinguishing between the two categories is critical because the category determines where a cost will appear in the financial statements.

- We recommend taking our Practice Quiz next, and then continuing with the rest of our Nonmanufacturing Overhead materials (see the full outline below).

- By focusing on activities and their drivers, organizations can make informed decisions, improve resource allocation, and enhance overall efficiency.

- Costs that are not related to the production of goods are called nonmanufacturing costs; they are also referred to as period costs.

- Non-manufacturing costs include those costs that are not incurred in the production process but are incurred for other business activities of the entity.

- Other manufacturing overhead items are factory building rent, maintenance and depreciation for production equipment, factory utilities, and quality control testing.

Applying Non-Manufacturing Costing Methods

Direct materials are raw materials that become an integral part of the finished goods. For the past 52 years, Harold Averkamp (CPA, MBA) hasworked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online. For the past 52 years, Harold Averkamp (CPA, MBA) has worked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online. Items such as plastic parts, metal parts and paint can be examples of manufacturing inventory. This account balance or this calculated amount will be matched with the sales amount on the income statement.

Net sales for 2010 totaled $57,800,000,000, resulting in operating profits of $6,300,000,000. Cost of sales represented the highest cost on the income statement at $26,600,000,000. The second highest cost on the income statement—selling and general and administrative expenses—totaled $22,800,000,000. These expenses are period costs, meaning they must be expensed in the period in which they are incurred. For accounting purposes, nonmanufacturing costs are expensed periodically (typically in the period they are incurred). However, for management objectives, managers frequently require the assignment of nonmanufacturing costs to goods.

However, various expenses are not directly related to manufacturing activities and are categorized as non-manufacturing costs. For manufacturing companies, product costs are only costs that are necessary to produce a finished product. As discussed earlier in the tutorial, product costs (i.e. manufacturing costs) consist of direct materials, direct labor, and factory overhead.

These minor types of materials, often called supplies or indirect materials, are included in manufacturing overhead, which we define later. For a manufacturer these are expenses outside of the manufacturing function. (However, interest expense and other nonoperating expenses are not included; they are reported separately.) These expenses are not considered to be product costs and are not allocated to items in inventory or to cost of goods sold.